At Valco Valley Tool & Die, we’re dedicated to providing our customers with a variety of services to meet their operations’ needs. While our specialty is our extensive line of readymade and customizable snap buttons, we also are able to offer a CNC turning center, a screw machine department, metal stamping department, and a four-slide department.

Along with these services, Valco is additionally adept at progressive die stamping, an essential process for many industries and one which offers a range of potential applications. Let’s take a moment to look at progressive die and stamping procedures and how they can benefit your products.

What is Progressive Metal Stamping?

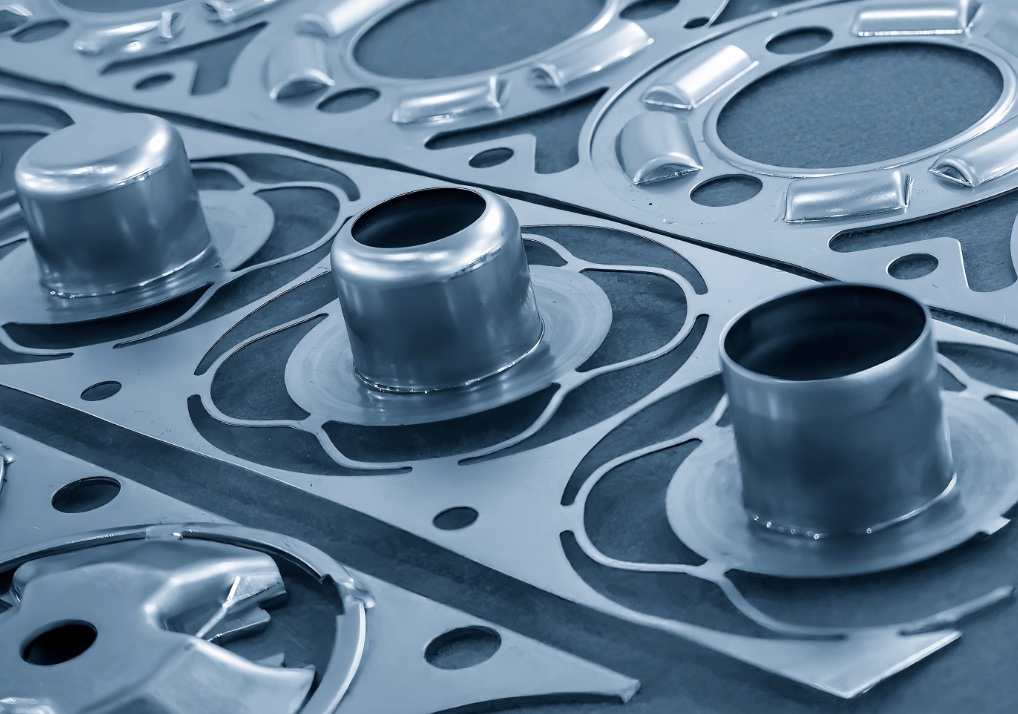

Progressive die stamping is a process used during metal forming that can create parts for a host of industries. Progressive dies are often utilized in higher-volume production, with their components engineered to function at higher rates of speed.

Dies for this method are often constructed from tool steel, due to its ability to endure high shock loading, maintain the precise cutting edge required, and stand up to abrasive forces employed during the process.

Metals commonly used in progressive die stamping include:

- Brass

- Steel

- Stainless steel

- Aluminum

- Copper

This form of stamping incorporates various work stations, with each facilitating a needed aspect of the part production. In progressive metal stamping, the part moves from station to station by way of a stock strip with the final product removed from the strip at completion.

The Process of Progressive Die Stamping

The progressive die stamping method often incorporates various metal modification techniques, such as:

- Bending

- Punching

- Coining

All of these modification techniques are accompanied by an automatic feeding system. This feeding system draws a strip of metal which unrolls from a coil, allowing each station to complete its given task leading to a finished part. The material that the part is ultimately separated from is called the carrying web, and this is relegated to a scrap bin to be recycled for later use once cutting is complete.

Because work is performed at each station during the progressive die stamping process, it is of paramount importance that a strip is advanced with precision so that the metal aligns within a few thousandths of an inch as each movement takes place.

When it comes to the actual process of progressive die and stamping, there are various steps required, which include:

- Stock strip layout and design – To start this process, manufacturers design the progressive die by utilizing advanced models. The graphical model is shaped into a finished tool by adjusting the position of every bend, punch, and hole on the strip.

- Tool steel and die set machining – When the stock strip design is complete, craftsmen then create the die blocks according to the exact specifications needed. This helps provide precise part repeatability, and these die blocks undergo quality control before production.

- Grinding and heat treating – Heat treatments help strengthen parts by raising the part beyond the alloy’s critical transformation temperature. The part is then cooled rapidly, improving durability and stability. Grinding also may be applied for parts needing higher dimension accuracy.

- Wire EDM – In this step, you can use an electrically charged brass wire to help further shape the die blocks with a controlled metal spark. Through this, you can achieve angles and intricate shapes.

- Die assembly – When all necessary steps have been completed, a die maker then assembles the die accordingly using precise instruments. The die maker will ensure it matches the exact specifications of the original design.

- Stamping parts – After assembly, the finished die is set up by a die setter in a stamping press. The metal strip then travels through the die where each process adds to the next. The strip is cut, punched, and bent into the form that was intended. This completes the production process.

- Packaging and shipping – The finished part is cut free from the feed line for further processing or assembly. Once that’s complete, the parts are ready to be shipped!

Why Your Company Should Invest in Progressive Dies

Companies determining whether to use a transfer die or a progressive die often take into account:

- The size of the part

- The complexity of the part

- The ultimate part volume required

Progressive die stamping is ideal when companies need a high volume of parts and are looking to be efficient and keep their production costs low.

Considering the complexity of progressive dies, there are a number of factors to keep in mind that relate to meeting the high demands of part quality, including:

- Blank position

- Blank boundary

- Pilots

- Stretch-web deformation

- The timing and interaction of upper and lower tools, pads, and carriers

Pilots, in particular, serve an essential function during the progressive die and stamping process, as they hold a strip in a specific location to allow total control during operation, providing the precise alignment discussed previously. These pilots are normally conical, or shaped in a fashion similar to bullets.

The Benefits of Progressive Die Stamping

By utilizing progressive die stamping for their production operations, a company can expect a number of worthwhile benefits, including:

- Increased production speed – Since the process utilizes a continuous feed for the chosen material, more parts are able to be produced more quickly. In fact, if a company is trying to produce at a high volume, progressive metal stamping provides an impressively low cycle time per part.

- Faster setup – Progressive die stamping reduces the setup time in comparison to other modes of fabrication and machining. It can take a number of setups for the traditional fabrication of parts, but this can be reduced down to a single setup, which in turn lowers costs.

- Reduction of scrap metal – With the various methodologies for manipulating your chosen metal (such as coining, bending, and punching), a large portion of the material is utilized, reducing scrap.

- Increased repeatability – By utilizing hard tooling, high volume runs are possible without increasing the degradation of dies. This in turn produces high-quality end products.

- Varied geometries for parts – Progressive die stamping is also adept at producing parts with numerous geometries in a single unit, all during a lone progressive die procedure.

- Lower cost – Because of all these aspects, progressive die stamping allows for a lower cost per part, helping your operations to reach optimum efficiency.

Additional benefits of progressive die and stamping can include:

- A higher press tonnage rate for heavier product materials

- Capability to supply multiple rows of your part for each press stroke

- Reduced material handling

- A wide array of impressions and shapes able to be stamped simultaneously

- Ability to maintain consistently close tolerances

Progressive Die Stamping Helps Various Industries

As you can see, progressive die stamping can supply companies with an assortment of advantages. Incorporating the process into your manufacturing is highly recommended so you can make the most of your company’s time.

Because of its impressive versatility, progressive die stamping can be utilized by a wide range of industries, but some which often use the process include:

Some good examples of famous products that utilize progressive die stamping are the pull tab lids on beverage cans and brake calipers found within your car, though of course thousands of everyday products have benefited from the progressive die process.

Contact Valco Valley Tool & Die Today for Progressive Metal Stamping

If you’re interested in utilizing progressive die stamping for your part production, reach out to Valco.

Our decades of experience in the industry, our dedicated engineering team, and our customization capabilities are all assets we look forward to putting to work for you. Contact us today!