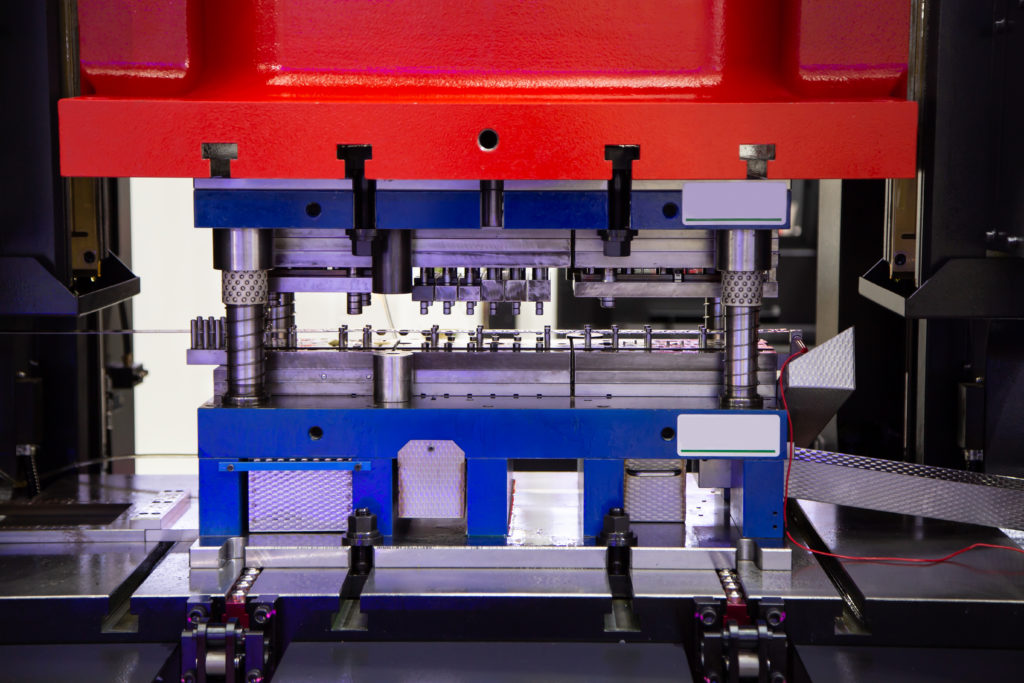

High-volume stamping uses specialized stamping presses and dies to transform flat metal strips into specialized parts and components. This process is known for its ability to combine cost-effectiveness with speed to create reliable outcomes, even in industries with demanding production requirements.

Learn more about our abilities in performing high-volume stamping below.

Advantages of Working with a High-Volume Metal Stamping Company

In the process of progressive metal stamping, metal coils are loaded onto a reel to unwind into a long continuous metal strip. The strip is then fed into a stamping press, which contains a progressive die. With each progression, the die performs various operations until the stamping is complete.

Advantages of using high-volume metal stamping include:

- Mass production – Creating a large number of parts at once is extremely beneficial in industries where bulk orders are necessary and stock needs to be refilled regularly.

- Efficiency – The process of high-volume metal stamping is very efficient and is often chosen due to its speed and accuracy.

- Precision – Creating a tooling mechanism may have a larger cost upfront, but once the tooling is in place, the cost per part begins to decrease. The tooling die also ensures that the parts are replicated accurately, which ensures precision and repeatability.

- Versatility – Stamping processes can be conducted on a variety of materials, including steel, aluminum, copper, and more. The material being worked with will depend on many factors, including strength, conductivity, corrosion resistance, and more.

FAQs About the Process of High-Volume Metal Stamping

To help you make the most informed decision about whether your application would benefit from high-volume metal stamping, we wanted to answer some of the frequently asked questions we receive. Learn more about high-volume or long-run metal stamping below.

How is quality ensured in high-volume stamping?

There are many quality control measures put into place during the high-volume stamping process, including regular inspections, dimensional checks, and material testing.

What industries use high-volume metal stamping?

Industries like automotive, electronics, aerospace, appliance manufacturing, and construction are known to use high-volume metal stamping. This is because they rely on parts that are produced in mass quantities with accuracy and efficiency.

What is the normal lead time for high-volume metal stampings?

The lead time of high-volume metal stamping varies based on the part complexity, material availability, and size of the production run. Regardless of these factors, the high-volume stamping process is typically faster when compared to other manufacturing methods because it has predetermined goals.

Can high-volume metal stamping be customized?

While long-run metal stamping is geared toward mass production, customization may still be achieved through tooling adjustments. Customizable factors include size, shape, and any other features specific to the client application.

Here are some things to consider if you are creating a custom part:

- Product use

- Dimensions required for the part

- Dimensions of the parts the new component will operate in conjunction with

- Load requirements

- Environment for use

- Additional details important to production

Allow Valco to Be Your Long-Run Metal Stamping Company

With over 50 years of industry experience, Valco/Valley Tool & Die is your go-to custom metal stamping company. Valco has a proud history in supplying quality products, service, and performance, and we are able to design, develop, and deliver the reliable parts you need for your application.

Our team is ISO 9001:2015 certified with design, and emphasis is placed on quality throughout the entire metal manufacturing process. Allow us to be your destination for long-run metal stampings.

Contact Our Team to Start a Project

If you’ve been looking for high-volume or long-run metal stamping services, be sure to consult our team to ensure that you always have enough parts on hand.

Reach out to us to get started!